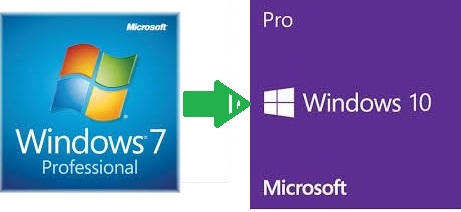

FASTech Excels @ Windows 7 to Windows 10 Control System Turn-Key Conversions

/0 Comments/in Blog, Press Release/by Ralph French

Stay current, secure, and productive with the latest Operating System! Have FASTech convert your legacy Windows 7 (or Win 2k) System to Win 10. We update or replace drivers, modify source code, test, and train – all as part of the turn key conversion!

FASTech Solutions Include:

- Specify & procure equipment

- In-office OS Install / programming / testing / documentation

- On-site installation / commissioning / training / startup support

- Post-installation remote service

PACK Expo (PMMI Show) Was Virtual But 2 To 18 Lane Stick Pack & Checkweighers Are Still Live!

/0 Comments/in Blog, Press Release, Trade Shows/by Ralph FrenchSince we missed you at Pack Expo this year, here is a virtual show of how we can meet your packaging production needs. Stick Pack machines ranging from 2 lane to 18 lane with 80 to 720 sticks per minute throughput. Each being accurately checked by the automated checkweigher with feedback to the filler. Give us a call 866-FASTech (866-327-3324) to find out more.

https://packexpo19.mapyourshow.com/8_0/exhibitor/exhibitor-details.cfm?exhid=02022459

FASTech Blows Out Automation Manufacturing Capacity by 35%

/0 Comments/in Blog, Industry News, Press Release/by Ralph FrenchDuring these unprecedented times FASTech is adapting to new conditions and constraints by expanding to a 2nd automation products / panel-building manufacturing facility. This allows us to continue to deliver business continuity and even increase capacity with safe and efficient workspaces for our employees, customers, and vendors.

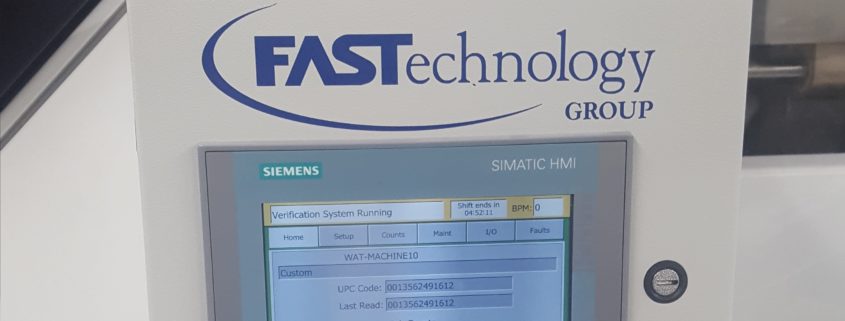

See FASTech’s UPC Verification System Case Study in Control Engineering Magazine

/0 Comments/in Blog, Press Release/by Ralph French

FASTechnology Group adds UPC Verification to Flexible Packaging (Bagging) Machines in Packaging Industry

Challenge: Supplement existing machines with an efficient, robust system to verify the correct pre-printed packaging is used for the product being packaged, 100% of the time.

Solution: Using the latest in PLC controls, HMI, and machine vision technology, as well as custom software and database development, FASTechnology Group created a system to read, compare and verify the UPC barcode of each and every product made against the plant’s ERP system.

Result: A system that integrates seamlessly with the existing production lines, monitoring the necessary aspects to improve line consistency and make mismatching of product to packaging a thing of the past.

Summary: In the Consumer Packaged Goods industry, a simple mismatch of pre-printed package to product can quickly spiral into a safety concern for consumers, not to mention countless dollars lost on wasted products, recalls, and downtime. For example, a packaging line cannot have peanuts going into a potato chip bag. The risks of only checking the spool of film prior to running the line doesn’t always cut it. When FASTechnology Group was tasked with modifying existing production lines to verify the UPC of each and every bag, the company was able to use the latest in industrial controls across a wide array of technologies to deliver a solution to the customer.

The system combines an industrial logic controller, a machine vision barcode reader, and custom server-side software to cross-reference the physical UPC with the one in the Plant Management Software. As one of FASTech’s customers states: “Using this system, we are able to limit the pulling of jobs down from the plant management system to only those scheduled for the current shift. This keeps the user interface out on the plant floor clean, simple to use, and efficient.”

Here is a link to the original Case Study…